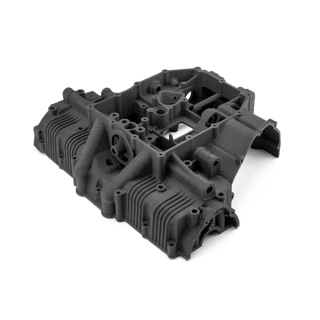

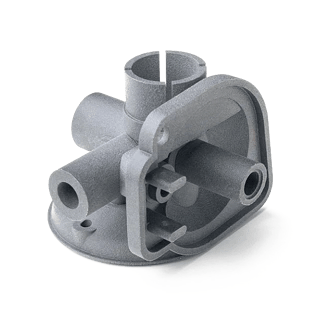

Get a quote for your 3D model

The first step to getting your 3D-printed parts is to upload your CAD files to our platform. We accept .STL, .STP, and .ZIP formats, ensuring compatibility with the most widely used design software. Once uploaded, our system will automatically analyze your model and generate an instant quote based on your specifications, including size, complexity, and quantity needed. This way, you get a clear and immediate overview of costs and production times, with no delays or complicated steps.